Hey there! So, you’re curious about advanced rigging design techniques? You’re in the right place! This nifty little corner of the internet is where we’ll dive into the fascinating world of rigging—specifically those super cool tactics that take standard techniques to a whole new level. Whether you’re a seasoned pro or a newbie just dipping your toes into rigging waters, hang tight. We’re going to explore some exciting stuff together.

Read Now : Innovative Rigging Equipment Solutions

Understanding the Core of Advanced Rigging Design Techniques

Alright, let’s ease into it. At its heart, advanced rigging design techniques revolve around creating systems that can handle complex, high-pressure tasks while maximizing efficiency and safety. Think of rigging as the unsung heroes of construction, film-making, and live events—holding things up, bringing things together, and ensuring everything is secure. The complexity of these tasks means basic rigging simply won’t cut it for more demanding operations.

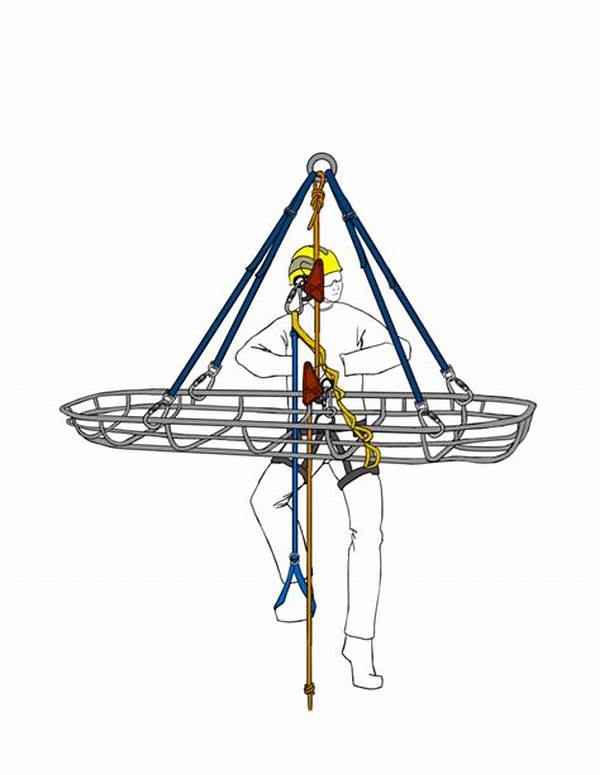

Incorporating advanced rigging design techniques means that every wire, pulley, and hoist is calibrated to perfection, working in harmony to create a seamless operation. You’ve got to love it when science and engineering meet real-world practicality! Advanced techniques involve sophisticated calculations and innovative solutions that anticipate potential issues before they arise. This way, everything from that massive stage set to the towering cranes on construction sites can operate smoothly and safely. And guess what? It’s kind of like a dance, where precision is key, and every component must perform its assigned role flawlessly.

Getting into the nitty-gritty of advanced rigging means understanding the specific requirements of your project and tailoring your solutions accordingly. These aren’t just cookie-cutter solutions you apply universally. They are bespoke, crafted meticulously to ensure excellence in execution. Whether the task involves lifting unconventional loads, dealing with unusual structures, or working in tricky environments, advanced rigging design techniques are the answer for making the impossible possible.

Key Components in Advanced Rigging Design Techniques

1. Load Analysis: Knowing the weight and force your rig needs to handle is the starting point of advanced rigging design techniques. It’s like setting the GPS for your journey—vital for knowing how you’ll get from A to B safely.

2. Material Selection: Not all ropes and pulleys are created equal. Picking the right materials is critical. In advanced rigging design techniques, the strength, flexibility, and durability of your materials make all the difference in the world.

3. Safety Calculations: Safety isn’t just a checkbox; it’s a process. With advanced rigging design techniques, safety calculations are consistently revisited, leaving no room for error because your well-being depends on it.

4. Custom Fabrication: Sometimes off-the-shelf just doesn’t cut it. Advanced rigging design techniques rely on custom fabrication to create unique components that fit your rigging challenge like a glove.

5. Dynamic Monitoring: Real-time monitoring systems are your best friends in advanced rigging design techniques. They keep an eye on every move your rig makes, ensuring everything works as planned.

Applications of Advanced Rigging Design Techniques

Let’s talk application because theory is nothing without a little real-world context, right? Advanced rigging design techniques find a home in industries as diverse as construction, entertainment, and even aerospace. If you’ve marveled at a massive concert stage or watched a skyscraper rise into the sky, thank advanced rigging. These techniques adapt to the unique demands of each project, making sure every engineered lift is both precise and safe.

In the entertainment industry, the swirling lights and high-flying acts wouldn’t be possible without refined rigging skills. Advanced rigging design techniques ensure all the pyrotechnics, stages, and set pieces move without a hitch. It’s about delivering the magic seamlessly, with every element choreographed for reliability and safety. On the flipside, in construction, these techniques are about brute strength and precision, often in unpredictable environments. From getting materials to seemingly unreachable places to ensuring structural integrity during repairs, they are critical in every major project.

10 Crucial Aspects of Advanced Rigging Design Techniques

Maximize Load Capacity

Advanced rigging design techniques ensure you’re getting the maximum load capacity from your setup without compromising safety. It’s all about detailed calculations and expert design.

Precision Engineering

Precision is key. These techniques involve meticulous measurements and engineering to make sure each component functions flawlessly, whether you’re lifting a grand piano or a steel beam.

Creative Problem-Solving

No two rigging situations are alike, making creative problem-solving a staple of advanced rigging design techniques. Designing custom solutions is where things get exciting.

Integration with Tech

Today’s rigs are smart. Through the integration of technology like sensors and AI, advanced rigging design techniques bring outdated manual systems into the future.

Read Now : “famous Actresses Emmy Oscar Accolades”

Safety First

Safety is always the number one priority. Advanced rigging design techniques prioritize redundant systems and fail-safes, so there’s always a plan B ready.

Training & Education

Regular training and education on new techniques keep rigging professionals at the top of their game. Staying current is crucial in this ever-evolving field.

Customization Abilities

Advanced techniques allow for high levels of customization, adapting to the unique demands of any project, big or small.

Forecasting and Planning

These techniques involve an extraordinary level of forecasting and planning, predicting potential snags before they become real problems.

Versatility Across Industries

They’re used across various industries, showcasing their adaptability from entertainment to architecture to construction.

Environmental Considerations

Eco-friendly practices are becoming integral in advanced rigging design techniques, balancing high performance with environmental responsibility.

Exploring the Future of Advanced Rigging Design Techniques

Imagine a future where advanced rigging design techniques continue to evolve, influenced by emerging technology and new industry needs. As more projects demand precision and creativity, the rigging world is jumping on advancements like virtual reality modeling and machine learning algorithms for predictive maintenance. These innovations are setting a new bar for what’s possible with rigging, driving efficiency, and safety to unimaginable heights. The integration of sustainable practices is becoming increasingly critical, with lightweight, smart materials that are not only strong but environmentally friendly.

In an era where the speed of industry developments often races ahead of the technological curve, staying updated with advanced rigging design techniques isn’t just about maintaining relevance; it’s about leading from the front. This means continuous learning and adaptation, ensuring every rig is equipped to face modern challenges effectively. From smart sensors to real-time analytics, advanced rigging is on the brink of a revolutionary leap that’s exciting to watch—and even more thrilling to be a part of.

Training Methods for Advanced Rigging Design Techniques

To master advanced rigging design techniques, understanding is only the beginning—you have to experience the methods hands-on. Training in this field is diverse, including workshops, simulation exercises, and on-site apprenticeships. Interactive training sessions often incorporate VR to mimic real-world rigging situations, providing a safe yet challenging platform for learning. Such immersive experiences are invaluable, enabling individuals to hone their skills in simulated environments that mirror actual job sites without the associated risks.

Moreover, collaboration with seasoned professionals offers insights that textbooks simply can’t provide. Advanced rigging isn’t just about applying learned techniques; it’s also about cultivating a mindset that anticipates complex challenges and thinks several steps ahead. By actively engaging in both classroom instruction and fieldwork, aspiring riggers acquire the nuanced understanding necessary to innovate within their practices. The training doesn’t end; it’s a career-long journey of skill enhancement and knowledge expansion, continuously influenced by the latest advancements in the industry.

Summarizing Advanced Rigging Design Techniques

At the core, advanced rigging design techniques represent a harmonious blend of technology, safety, and engineering prowess. As industries expand and evolve, so do the complexities they bring. Having a robust understanding of these techniques is integral to adapting and thriving in such dynamic environments. Mastery here results in operations that are not only safe and efficient but also innovative and tailored to specific needs.

In wrapping up, venturing into the advanced realms of rigging is not just a journey through intricate systems and calculations. It’s an exploration of creativity, problem-solving, and continuous improvement. Whether you are designing a rig for a world-class event, a massive construction project, or a unique artistic display, these advanced methods are your toolkit for success. Dive deep, learn continuously, and enjoy the thrill of transforming the extraordinary into the standard with advanced rigging design techniques.